INNOVATIVE METAL BUILDING SYSTEMS

Butler Manufacturing™

Since 1989, The Tamora Group has proudly partnered with Butler Manufacturing™ to deliver top-tier steel building systems across Pennsylvania. For over 30 years, we’ve brought unmatched quality and efficiency to commercial, industrial, and retail construction through Butler’s innovative metal building solutions and our streamlined Design-Build approach.

As your trusted local Butler Builder®, we serve all of Pennsylvania and extend our expertise to northern Delaware, northeast Maryland, and southern New Jersey—and beyond.

Whether you’re operating in the frosty north of Canada or the warm climate of southern Mexico, The Tamora Group is ready to support your project. We offer the same cost-effective, high-performance Butler building systems wherever you are. Let us design and deliver a custom metal building solution tailored to your business needs—with the reliability and speed you expect from a Butler Builder.

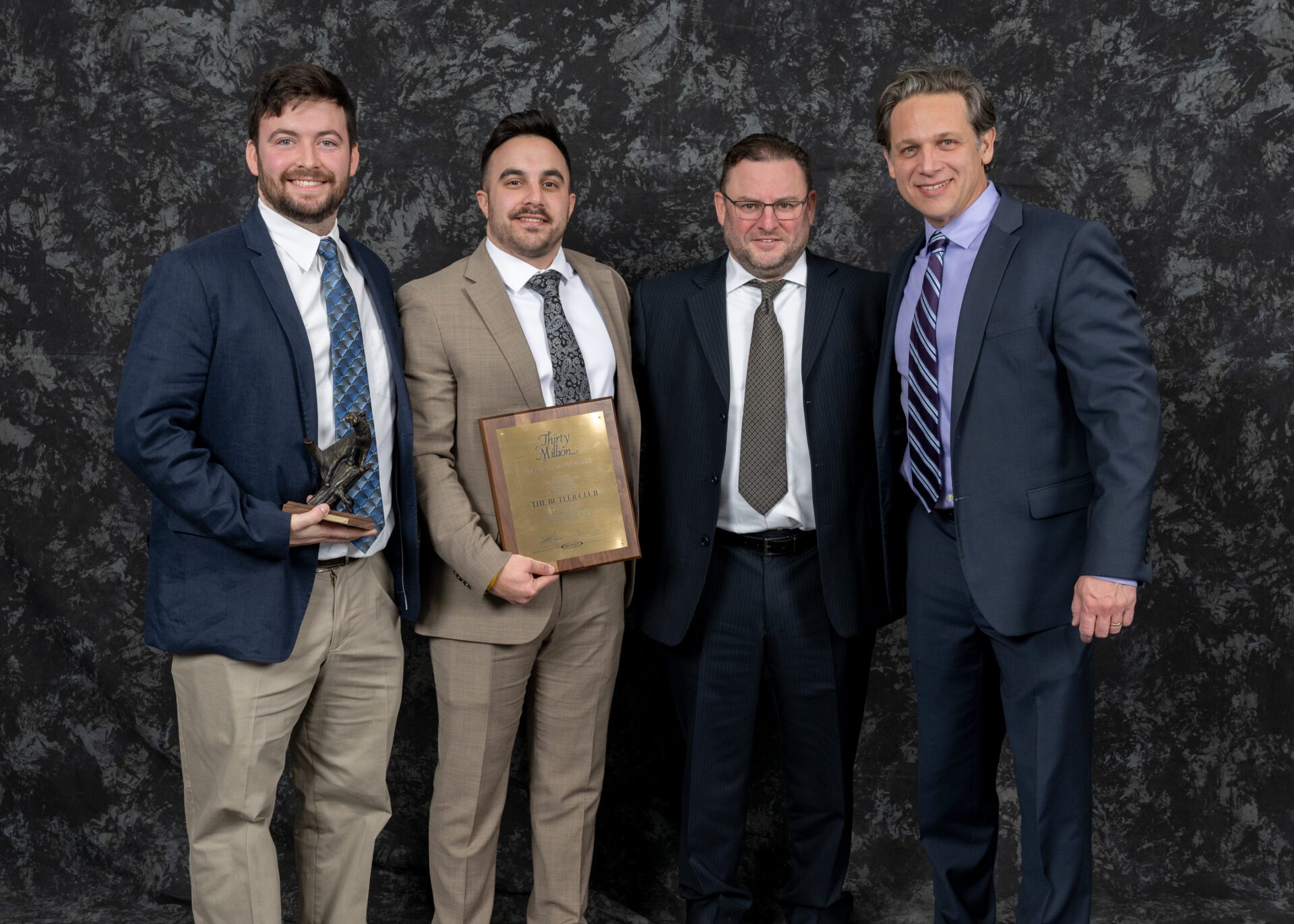

Awards and Associations

“The Butler Club” 10 Million, 15 Million, 20 Million, and 30 Million in Sales

What Makes Butler the Right Choice for Commercial and Industrial Projects?

There are very few projects that can’t benefit from a Butler Building—and that’s no exaggeration. Their unmatched versatility and custom-engineered solutions make them ideal for a wide range of industries and applications.

Consider the growing number of businesses that need both warehouse functionality and office space under one roof. Whether it’s for visibility across operations, convenience of an on-site administrative hub, or an integrated office-warehouse facilities Butler can offer smart, streamlined solutions.

Thanks to the flexibility of pre-engineered metal systems, features like insulated metal panels can be easily incorporated to meet specialized needs. From cold storage and food distribution to automotive service centers and agricultural equipment repair, businesses of all kinds have found reliable, energy-efficient homes in our buildings.

Looking ahead, Butler buildings also make future expansion straightforward. That warehouse and office you just built? When you’re ready to grow, The Tamora Group can seamlessly add more square footage or connect a new facility—faster and more affordably than traditional construction methods allow.

More Than Metal Buildings

Sometimes you just need to fix that leaky roof or repair or renovate parts of a facility. We’ve got you covered.

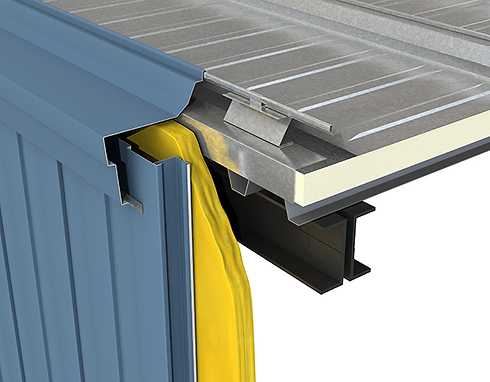

With Butler’s powerful roofing and re-roofing systems, we can fix your old, damaged roof easily. Often, a new Butler watertight, highly-reflective roof can be installed while your business continues below. These systems let us create a roof slope where there wasn’t before—a flat roof creates more area for water and snow to collect and damage your building.

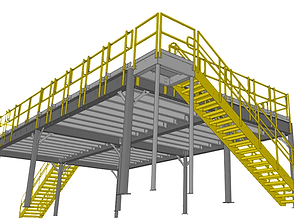

Owners also often need more floor space in an existing facility or a standalone area to ease worker flow. Butler makes this easy with products like the Express Mezz™ system. Customized size and load capacity make it ideal for adding extra office or storage space or creating an elevated platform on production floors.

Highly efficient and heavily-insulated wall and metal roofing systems are part of the foundation of a Butler building system. If you want an alternative to insulated metal panels, products like the Shadowall EX™ bring you a cost-effective option without sacrificing amazing performance.

Material and Energy Efficient Design

When we design your next metal building with a Butler building system, it can help you earn LEED credits. The steel structures constructed with Butler systems are made from over 70% recycled materials—making steel buildings a sustainable building solution.

The “pre-engineered” part of the equation also saves on materials required and greatly reduces material waste. These savings are directly reflected in your final price. Buildings are designed for the pieces to be pre drilled and shaped to fit perfectly together. This gives an experienced team a great opportunity to accurately and quickly erect the system.

During the design process, powerful software determines the most economical use of materials and building parts arrive arranged in the order they should be erected. This saves time on the job site and doesn’t create any of the steel waste of conventional construction.

Your future industrial or commercial steel building will save you and your business money. Butler’s energy-efficient components live up to the high demands of cold storage operations and keep heating and cooling costs low.

Combined with Butler’s reflective roofing and wall coatings, your building will lower energy demands and save you in operating costs. Butler metal building systems are also low-maintenance, with decades of in-place, weathertight performance.

Why Butler Manufacturing™?

Butler translated the stock tank idea to building construction with their first pre-engineered car garage being sold around 1910—interestingly enough, that building stood for more than 45 years! Continuously improving its products, Butler moved into other ventures and eventually began constructing pre-engineered metal buildings.

Butler Manufacturing opened the doors of its Research and Development lab, the Butler Research Center, in 1959. Their forward-thinking approach is apparent, from the industry-leading MR-24® to the cutting-edge melding of pre-engineered steel building systems with conventional methods in their Hybrid Building Systems.

Working With a Butler Builder®

Your project will flow smoothly with our experience at the drafting table.

Featured Butler Buildings that The Tamora Group has completed.

Broomall Fire Company #53

Deacon Industrial Supply Co.